Software for the asphalt plants

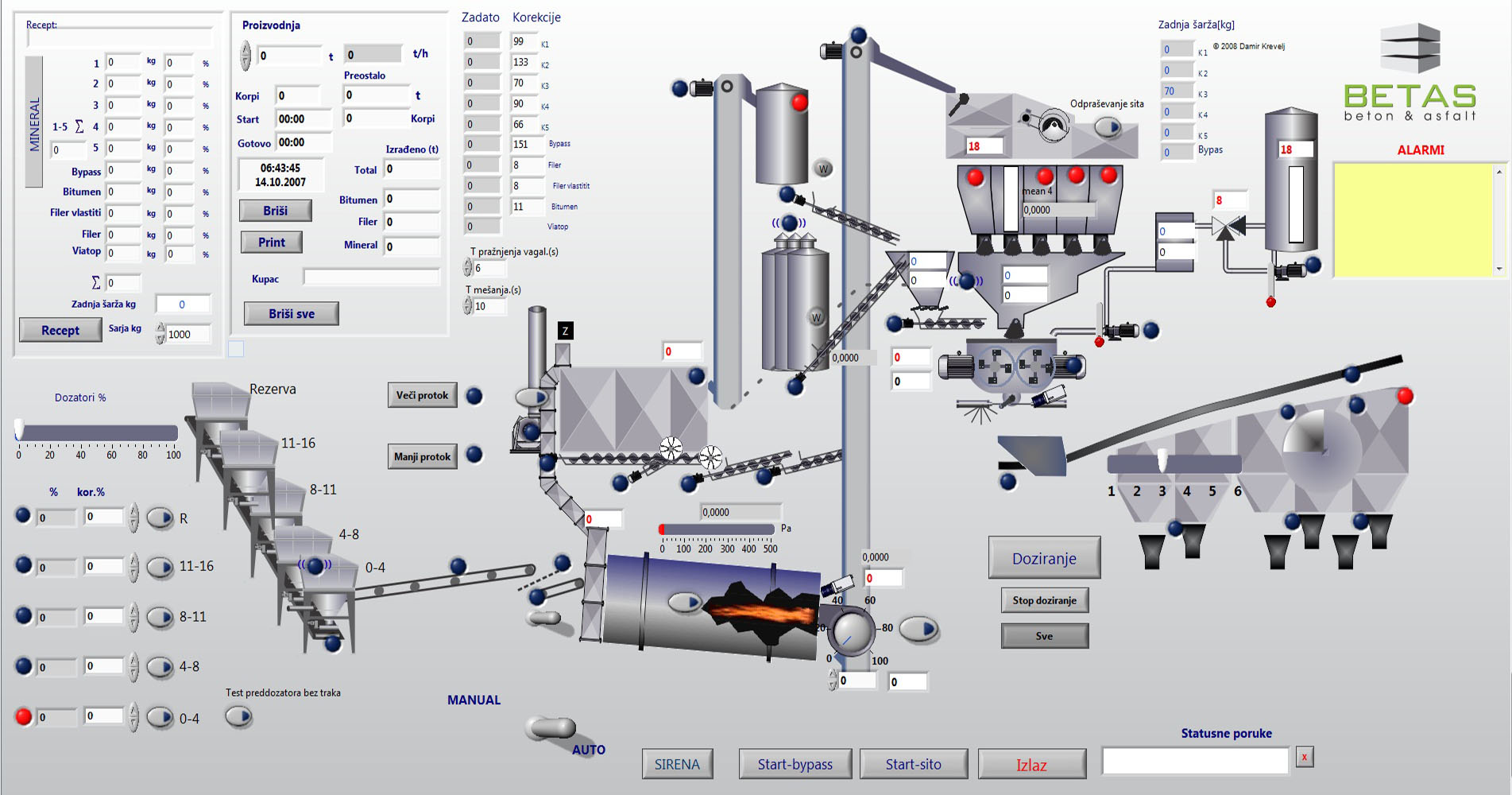

The process of asphalt production is rather complicated since the time of the input materials supply has to be calculated with the delivery time of output material. Beside this all of the process parameters have to be taken into account, such as heating time of bitumen, quantity of added aggregate, time of additives delivery, quantity of additives, humidity and granulation of aggregate. Many of these parameters further depend on quantity of ordered asphalt that influences the heating and mixing time. Such a complicated process can’t be controlled manually. For this reason we developed a computer software that considers all required parameters and optimally guides the asphalt production process.

The software is user friendly and reliable. The user can manually set the quantities of all materials to produce a custom made mixture of asphalt or choose one of the standardized mixtures that are usually used in civil engineering. The user can track all production phases of asphalt, beginning with material supply, their processing and ending with the final state of the produced asphalt. This way the user has a total control over the technological process of asphalt production. The program records production statistics and warns the user about the failures in the production process and malfunction of electric or mechanic devices.

Our software is modern and innovative. It is based on years of experience with asphalt production and tailored to the needs of asphalt producers. User can choose among several languages. The chosen language is used on the screen commands and menus, at the data input, printed output and in all recorded statistics. In case of special needs the program can be modified and tailored to the customer’s wishes.

For additional informations about software for asphalt plants call us or send an inquiry.

00386 41 645 155 This email address is being protected from spambots. You need JavaScript enabled to view it. Inquiry

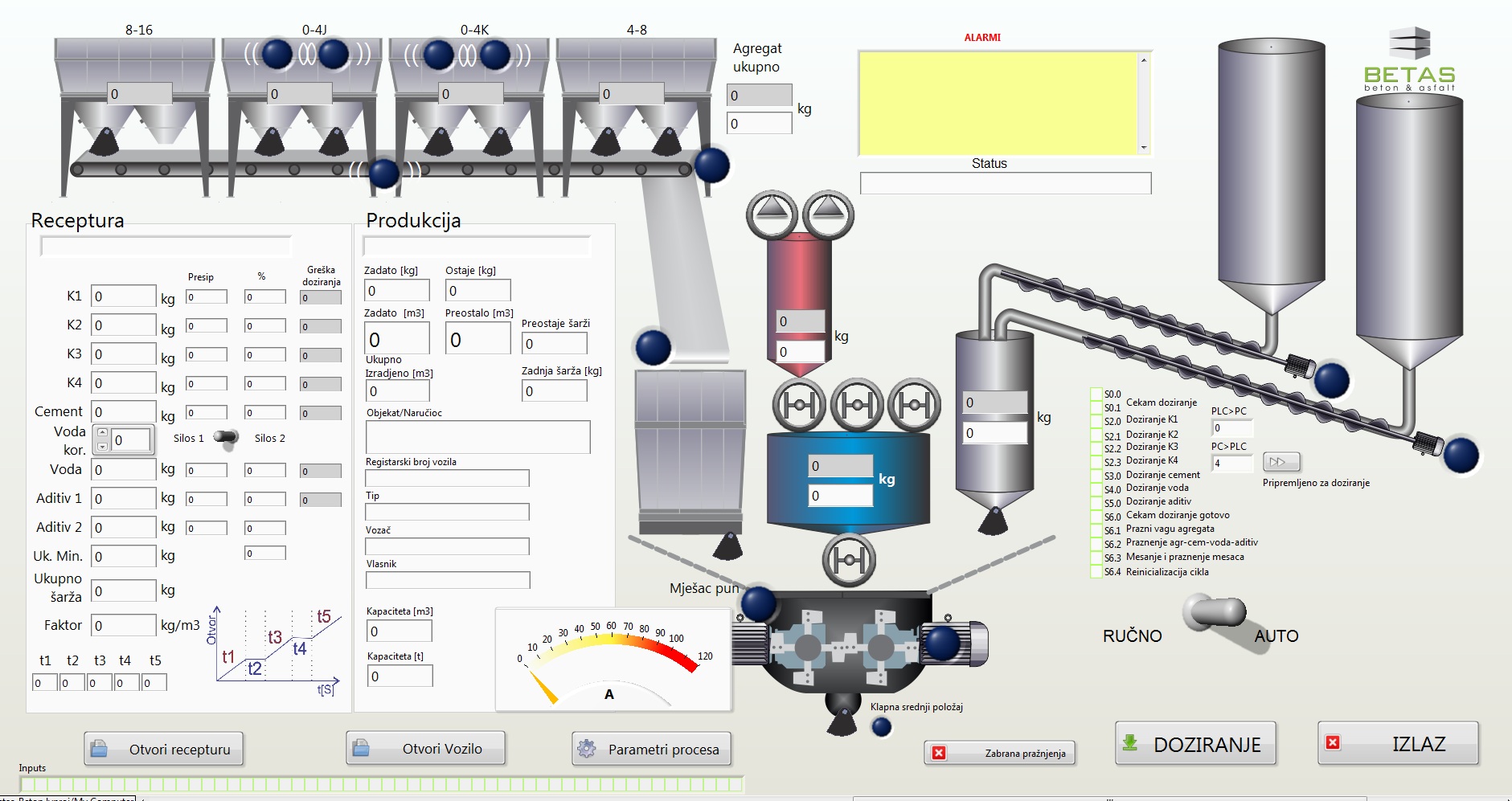

The program is reliable and user friendly. The plant operator can manually set the proportions of added materials and can thus produce the concrete mix according to individual specifications of the customer. The operator can also choose among many of the standardized mixtures that are usually used in civil engineering. All production phases are displayed on screen so the plant operator has a complete control over technological process of concrete production. The program tracks the complete production statistics and warns about any malfunction of the production process.

Our software is modern and innovative. It was developed on basis of years of experience with the concrete production and is adapted to the needs of concrete producers. The user can choose the language among several options. In the chosen language the screen menus are displayed and it is used at the data input, document printing and presentation of statistics. In case of special needs the program can be additionally adapted to the customer’s wishes and requirements.

For additional informations about software for concrete plants call us or send an inquiry.

Process of concrete production is in technological sense approximately as requiring as the process of asphalt production, however the timing is even more delicate. The delivery time of concrete must be precisely matched with the moment of demand and consumption. While asphalt after solidification still can be recovered, melt and reused, this is not possible at solidified concrete. If the synchronization between producer and consumer of the fresh concrete is not correct a considerable amount of concrete can be lost, in the worst case the solidified concrete can even destroy equipment and machines (for example mixers, tanks, tools and various transporting systems). For this reason the time of fresh concrete delivery has to be precisely matched with the time of consumption.

At the concrete production several processing parameters have to be considered. Among the most important are the quantity of aggregate, time and quantity of the adder cement and additives, humidity and granulation of the aggregate. All of these parameters further depend on quantity of ordered fresh concrete that influences the preparation time and thus the time of delivery of the fresh concrete. Such a process can’t be controlled manually. Therefore we developed a computer software for optimal control of the production process. The program measures all the necessary processing parameters and controls the actuating systems (for example heating system, transporting system for delivery of additives, mixers).